We test your algorithms

Hardware in the Loop-Simulation (HIL)

HIL applications are an extension of the sensor simulation. Several, even different Simulyzer boxes are linked and synchronized. In this way, for example, all sensors of different types belonging to an airbag system can be synchronized to generate data streams against an ECU.

Simple application

HIL in practice

Often up to 6 PSI5 simulators (or more) plus several SPI simulators are operated together. For coordination there is a superordinate configuration that determines which Simulyzers are used, which signal tracks are used by which Simulyzers and which detailed configurations with the bus parameters are to be used. Using this superordinate configuration, the API is very easy to use and is limited to about 4 calls to be made. A continuous control of the sensor signals is also possible.

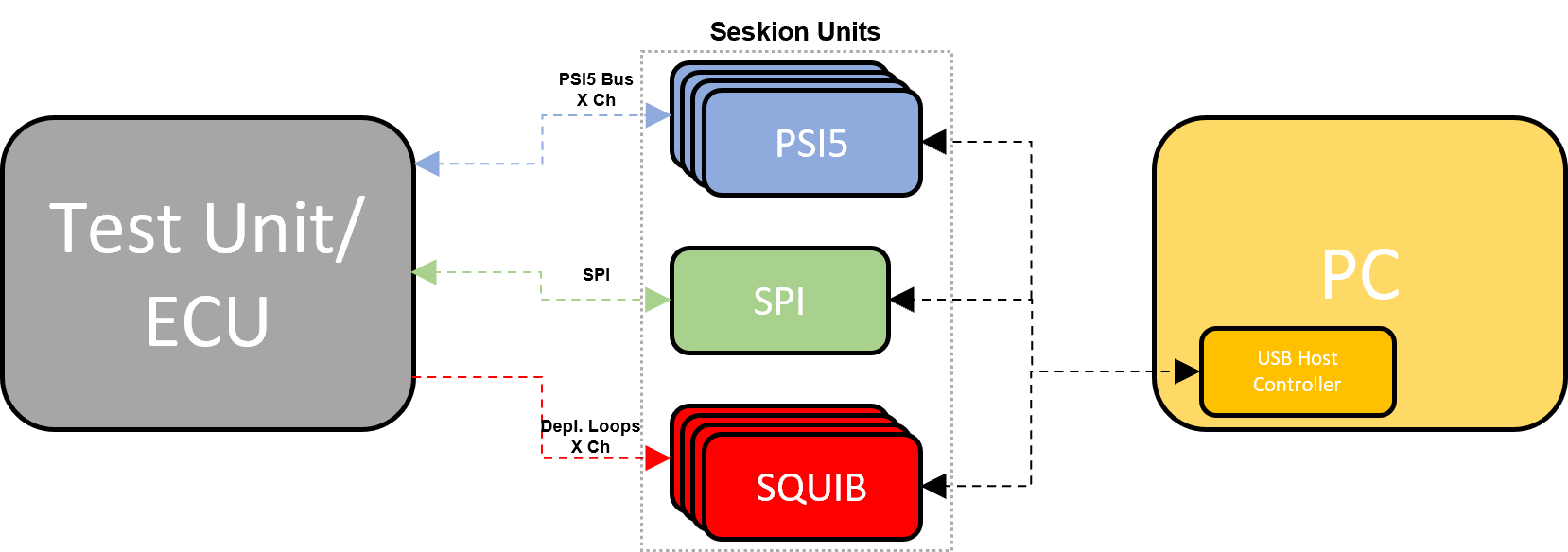

HiL-Simulation for Airbag ECU

To generate a complete HIL simulation for an airbag control unit, the internal acceleration sensor signals of the control unit (SPI) and the peripheral acceleration and pressure sensor signals (PSI5) must be connected. Also the ignition timing can be measured and analyzed by using the SQUIB box. Furthermore, a PC system connected to the simulators via a USB port/network is used for data processing.

Often up to 6 or more PSI5-Simulyzer are operated together with several SPI-Simulyzer. For coordination there is a superordinate configuration, which determines which Simulyzer is used, which signal traces are used by which Simulyzer and which detailed configurations are to be used with the bus parameters. By using the superordinate configuration, the operation of the API is very simple. A continuous control of the sensor signals can also be made.